| PROPERTIES | STANDARD | RESULTS |

|---|---|---|

| Physical State | Viscous paste | |

| Appearance | Opaque | |

| Colour | White, black, grey | |

| Density (gm/cc) | 1.35-1.50 | |

| Tensile Strength (mPa) | ASTM D 412: 2016 | Approx. 2 |

| Elongation (%) | ASTM D 412: 2016 | > 500 |

| Shore A | ASTM D 2240: 2015 | 34 |

| MAF | ASTM C 719: 2014 | ±50 % |

| Depth Cure | Approx.1-2mm/ day | |

| Effects of Heat Ageing | ASTM C 1246:2017 | No cracking and chalking |

| Stain and Colour Change | ASTM C 510:2016 | No staining and no colour change |

| Tack Free | ASTM C 679:2015 | No transfer of test specimen to the polythene film @ 72 hrs |

| Adhesion-In-Peel Strength (N) | ASTM C 794:2018 | 74.2 N (cohesive failure within the sealant and no adhesive bond loss b/w adhesive and substrate) |

Benefits of Trubuild Sealmaster Flexi are -

High adhesive strength on most substrates

Superior mechanical properties

Permanently elastic after cure

UV resistant

Excellent weather resistance

Can be painted

Does not contain isocyanates, hence safe

Trubuild Sealmaster Flexi is available in the following packaging:

600 ml

- For gap filling

- Sealing control and expansion joint

- Bonding of metals, glass, ceramics

Professional Sealants

Professional Sealants

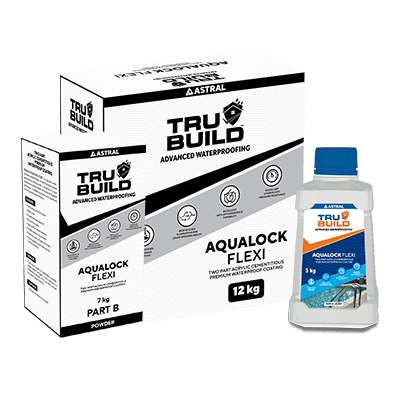

Roof Waterproofing

Roof Waterproofing

Substructure Waterproofing

Substructure Waterproofing Tiling and Grouting

Tiling and Grouting

Water Tanks and Other Areas

Water Tanks and Other Areas