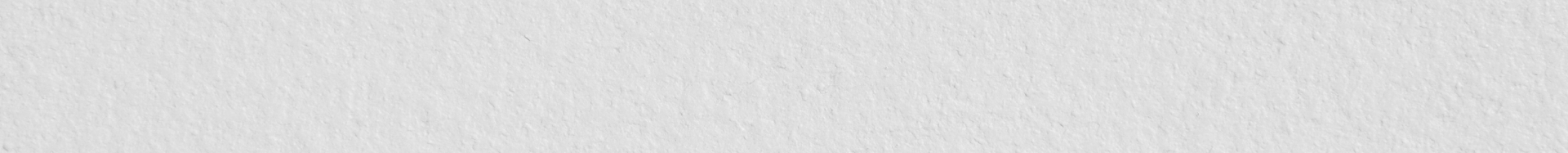

How to Choose a Joint Sealant? Here’s a Step-by-Step Guide

May 14, 2024

Concrete, like most materials, expands and contracts with temperature changes. This slow but steady change is important when it comes to construction work, like concrete buildings. To handle this movement and prevent cracks, builders leave small gaps called joints where different parts of the structure meet. These tiny spaces are filled with a special material called joint sealants, which act as a barrier to let moisture, dirt, and debris fill in. Using these sealants is important to keep the structures strong and safe for a long time.

The different types of sealants are each designed for a specific job. Some of them are waterproofing sealants, while others can handle extreme temperatures. Some even resist chemicals. Picking the right joint sealant is like picking the right tool for the job. If you use the wrong type of sealant, it might crack, lose its grip, or even break down quickly.

Here is a comprehensive guide to help you pick the right product for the job.

Step-by-Step Guide to Choosing the Right Joint Sealant

Step 1: Assess the joint design

Figure out what your project needs and the size of the joints. Think about whether you need it to be waterproof, if it is for indoor or outdoor use, or if the sealant needs to be painted over. This will help you choose the best type of sealant.

Step 2: Understand the materials being sealed

Different sealants work better on various surface materials. Make sure a compatible joint sealant is according to the materials you are working with. Otherwise, it could cause problems like swelling, hardening, or discolouration.

Step 3: Chart expected performance (like how much movement it needs to handle)

Joint sealants need to handle different amounts of movement in the building. High-performance sealants are great for strong, stable applications, while lower-performance ones are better for areas that move a lot, like around windows and doors.

Step 4: Evaluate sealant characteristics

Look at how flexible and strong the joint sealant is, and how well it handles repeated stress. The type of plastic and any added ingredients affect its performance. This indicates how durable and flexible the sealant will be.

Step 5: Calculate installation and maintenance costs

After narrowing down your joint sealant options, consider your budget. Cheaper sealants might need to be replaced more often, while more expensive ones might be too costly upfront. Compare the prices, how long they last, and any maintenance costs to find the best value for your project.

Carefully considering the factors can help you determine the most suitable joint sealant for your specific project. While different sealants have different benefits, Trubuild Sealmaster Flexi is an exceptional waterproofing sealant offering solid and reliable bonding.

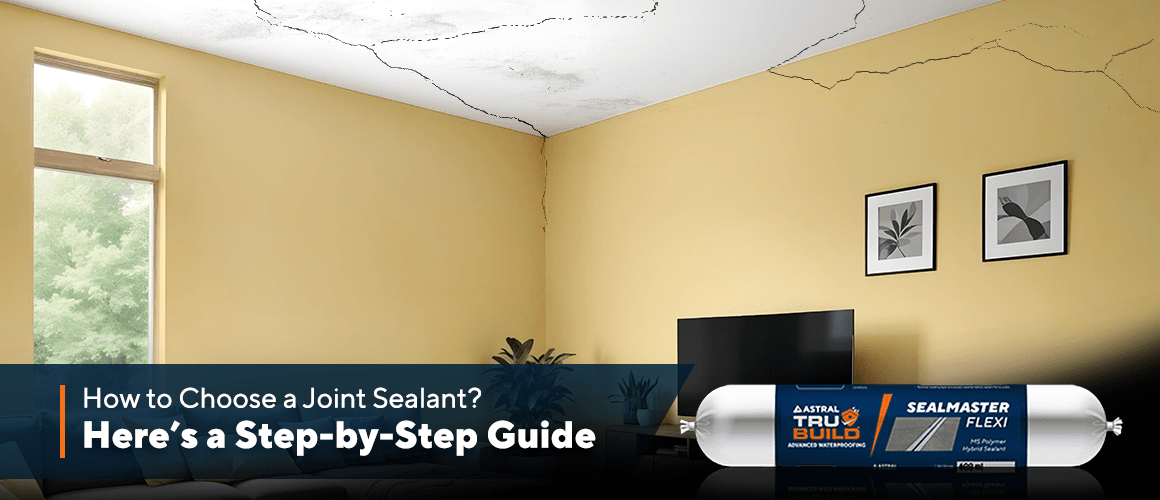

Trubuild Sealmaster Flexi: Advanced Joint Sealant for Leak-proof Bonding

Trubuild Sealmaster Flexi is a high-performance, single-component elastic sealant based on MS-Polymer technology. This moisture-curing sealant forms a tough, durable seal with excellent adhesion to a variety of substrates.

- Strong adhesion to most materials

- UV-resistant and paintable

- Ideal for exterior applications

- Durable waterproofing sealant

- Isocyanate-free for safer handling

- Permanently elastic after curing

- Versatile application

Choosing the best joint sealant and seamless sealant application is the key to durable and effective sealing. By understanding the nuances of sealant types and using the right techniques, you can ensure durable and reliable protection for your projects.

Professional Sealants

Professional Sealants

Roof Waterproofing

Roof Waterproofing

Substructure Waterproofing

Substructure Waterproofing  Tiling and Grouting

Tiling and Grouting

Water Tanks and Other Areas

Water Tanks and Other Areas