| PROPERTIES | STANDARD | RESULTS |

|---|---|---|

| PART - A | ||

| Chemical Base | Epoxy Resin | |

| Physical State | Viscous Liquid | |

| Appearance | Transparent | |

| Color | Colorless | |

| EEW | ASTM D-1652-11 | 170-190 |

| Viscosity @25°C | ASTM D-4402 | 500-1000 cps |

| Specific Gravity | 1.15 | |

| PART-B | ||

| Chemical Base | Polyamide Hardener | |

| Physical State | Viscous Liquid | |

| Appearance | Transparent | |

| Color | Yellow | |

| Amine Value | IS 9162-1979 | 350-400 |

| Viscosity @25°C | ASTM D-4402 | 8000-12000 cps |

| Specific Gravity | 0.98 | |

| Mixing Ratio | 100:50 | |

| Mix Viscosity @35°C | ASTM D 4402 | 500-1500 cps |

| Mix Viscosity @40°C | ASTM D 4402 | 2000-3000 cps |

| Mix Density | 1.12 gm/cc | |

| Pot Life @ 30°C | Visual | 150-180 min in 100 gm mix |

| Pot Life @ 35°C | Visual | 100-130 min in 100 gm mix |

| Hardening Time | 12-15 Hrs | |

| Curing Time | 24 Hrs | |

| Application Temperature | 10-35°C | |

| Shore-D-Hardness | ASTM D 2240 | 60-65 |

| Compressive Strength (After 24 Hrs) | ASTM C 597 | 45 N/mm2 |

| Compressive Strength With Silica | ASTM C 597 | 55 N/mm2 |

| In 2:1:8 Ratio (after 7 day) | ||

| Lap Shear Strength (After 24 Hrs) | 70-100 kg/cm2 |

Benefits of Trubuild TCSR 555 are -

It has excellent adhesion and strength on various construction substrates and is easy to apply due to low mix viscosity

It has very low shrinkage and high open time

Easy to apply

Free flowing

Moisture insensitive

High density ensures complete water displacement

High mechanical strength even after hardening under water

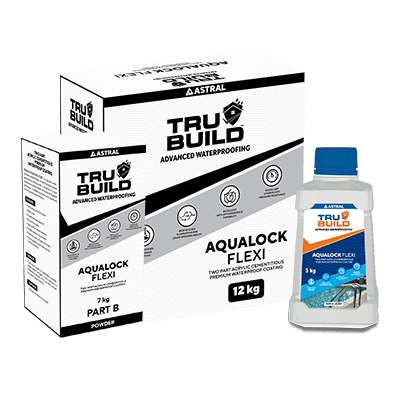

Trubuild TCSR 555 is available in the following packaging:

300 gm set

1.5 Kg set

7.5 Kg set

- Excellent system for bonding of old to new concrete/mortar, repair old concrete structure and it can be extended further. It can be injected to seal damp & wet cracks more than 2mm by high-pressure injection and for better adhesion of concrete and steel.

Professional Sealants

Professional Sealants

Roof Waterproofing

Roof Waterproofing

Substructure Waterproofing

Substructure Waterproofing Tiling and Grouting

Tiling and Grouting

Water Tanks and Other Areas

Water Tanks and Other Areas